Concept

Concept

What motive us?

The ceramic industry is a millenary industry, with some production aspects that have the potential for optimization and would significantly impact performance. One of these issues is color replication in production.

Our Solution

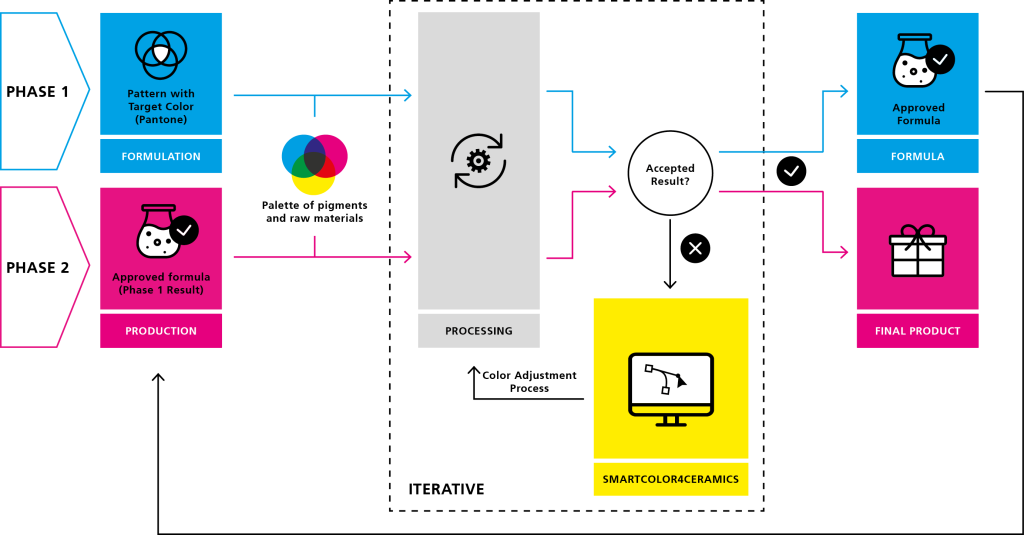

SmartColor4Ceramics proposes to optimize the process of color (re)creation in glazes for the ceramic industry. By developing an integrated software solution powered with machine learning algorithms, it is intended to automate the iterative suggestion of the best combination of pigments and production parameters, a subjective and manual task that currently depends exclusively on human expertise. To this end, a specialized database will be created for experiences mapping, enriched with data modeling techniques and computational learning. The solution will be tested and validated in a real ceramics production environment.

Our Objectives

Creation of a map of experiments: Database on the proportions of pigments and other raw materials, as well as additional production variables, and their correlation with objective results of color validation in the produced sample

Automation of the process of evaluating the color obtained, making it less dependent on the expertise of the operator, using instruments such as spectrophotometer or colorimeter

Optimization of the mixture/parameters for better results in the formulation of new colors (and, to a lesser extent, in production), in order to reduce the number of adjustment attempts, resulting in waste reduction and gains in time and resources

Color stability analysis (through the dispersion of results in the experiment map) for prioritization of more stable colors, in order to minimize defects in production.